E38 Fuel Tank Sealer Rusty Hole DIY

How to seal rusty gas tank

If your car seems to loose fuel and you can’t keep it up filling at gas station maybe the fuel tank is leaking through tiny hole. My car (BMW E38) consumes a lot of fuel (about 13MPG) so small leak would be difficult to notice, but if your trip computer and actual consumption, which you can do dividing miles driven by total fuel consumed, tells the story.

Signs that your car might be losing fuel without burning it in the engine:

- You can usually smell gasoline when approaching car first thing in the morning. If the hole in the tank is small enough, you cannot always see visible clues.

- Look underneath for unusual clear or shiny spots. Gasoline is a perfect solvent and can be used as a cleaner. When it seeps through the hole in the tank it most likely will wash away any dirt and oil. Wet gasoline stain can travel further down the tank bottom to the lowest point. If it doesn’t evaporate until this point, fuel drops will collect on the ground.

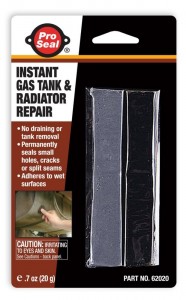

There are special products for repairing small leaks on the tank. Usually it is a 2 part plastic compound sealer which you have to mix and apply on the rusty hole before it hardens and seals it.

Steps to patch your rusty tank:

- Locate the spot and evaluate hole size. What might seem like a little weeping hole at first could become large falling part when you remove dirt, paint and rust from this spot. Rust on the car is like cancer, you can’t see the whole picture until you investigate. If you find the hole is quite big and you can even stick a finger or 2 in it maybe you should consider replacing whole tank instead of trying to repair it. Driving with this condition could be dangerous.

- If the spot is reasonable or you are tight on the budget continue with cleaning the area with a wire brush or coarse sand paper. You can also apply brake cleaner and wipe with paper towel. Clean until all rusty parts will fall off and you are left with a semi clean area. It doesn’t have to be perfectly shiny but the smoother it will be the easier to patch.

- Read the instructions on the package on how to prepare the patch. Usually you have to take 2 equal parts of the material and mix it by hand until color will become uniform. Make a pancake in your hand and apply this to the hole. At first, it might be lose and seem like falling off, but tap it with your fingers until it begins to stick better. You can make the patch fatter on the hole area and even push it in a bit in the tank to get a stronger seal.

- Wait at least 10-20 minutes before driving the car to not disturb the hardening phase. The patch might feel hot to the touch. This is because chemical reactions are taking place and new bonds with the metal are created during curing phase. After a while, the patch changes color and might blend with the rest of the tank color, so no one could even notice without close inspection.

- Periodically check the patch area every few days to make sure you don’t have any further leaks.

Fuel can disappear not only from the tank with a hole in it but also from lose fuel hoses in the engine bay. It took me a while to notice this on my car during winter season. When I first started the car in the cold morning I could smell gasoline for the first few minutes, but after stopping and checking under hood, nothing was apparent. Only later I managed to catch the area where fuel was leaking. It was near the fuel injector on fuel rail return hose connection. The hose clamp was loose from the previous fix where I changed intake manifold gasket. I didn’t tighten hose clamp enough and fuel was able to seep through the tiny opening. When the car warmed up, rubber hose did to and expanded thus making leak harder to find. It was tiny leak and caused some idling issues, but otherwise you couldn’t tell at first. So this example only shows that with cars you have to be creative and curious because not every problem is the same.

If the tank is full or fuel level is higher that the hole you found it is better to siphon fuel out first before patching. This is because leaking fuel can inhibit the compound from proper adhesion and the leak might reappear later on.

There are other ways to repair rusty fuel tanks like welding a patch. But this usually involves taking fuel tank apart and it is not very DIY if you haven’t got MIG welder at home or garage.